MTX is a non-contact, auto-focusing, self-calibrating white light scanning interferometer.

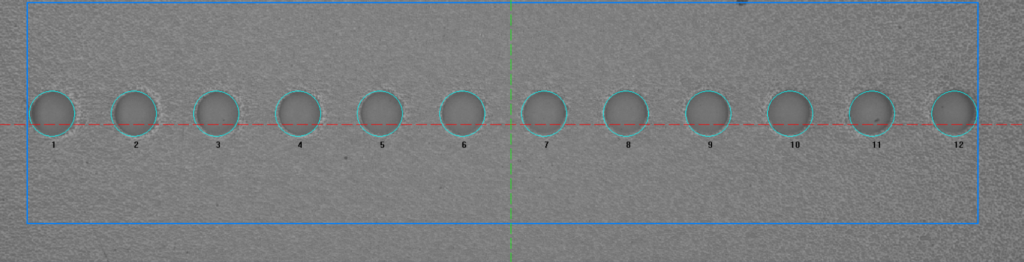

The product utilizes white light and red light interference principles to reconstruct the geometric shape of optical fiber end faces, thereby calculating various technical parameters. In addition to measuring multi-core fiber optic connectors such as MT and MTRJ , it is also compatible with conventional single-core connectors like FC, SC, ST, LC, and MU. This makes it an essential inspection device in the production process of fiber optic connectors.

1. Fully automatic focusing and calibration

The device employs precision automatic slide stages and control algorithms to rapidly and accurately locate interference signals. In multi-core measurement mode, it automatically identifies the starting position and initiates scanning, while in single-core mode, it automatically locates the position with the clearest signal before starting measurement. The internal reference mirror is also hardware-controlled to enable automatic flat mirror calibration.

2. Extremely Fast Testing Efficiency

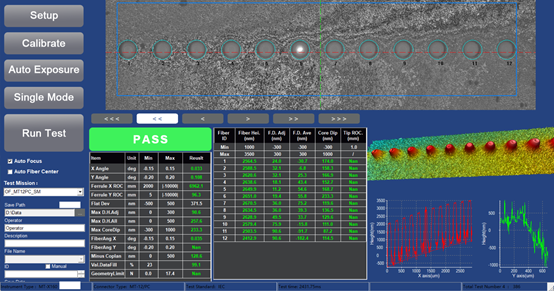

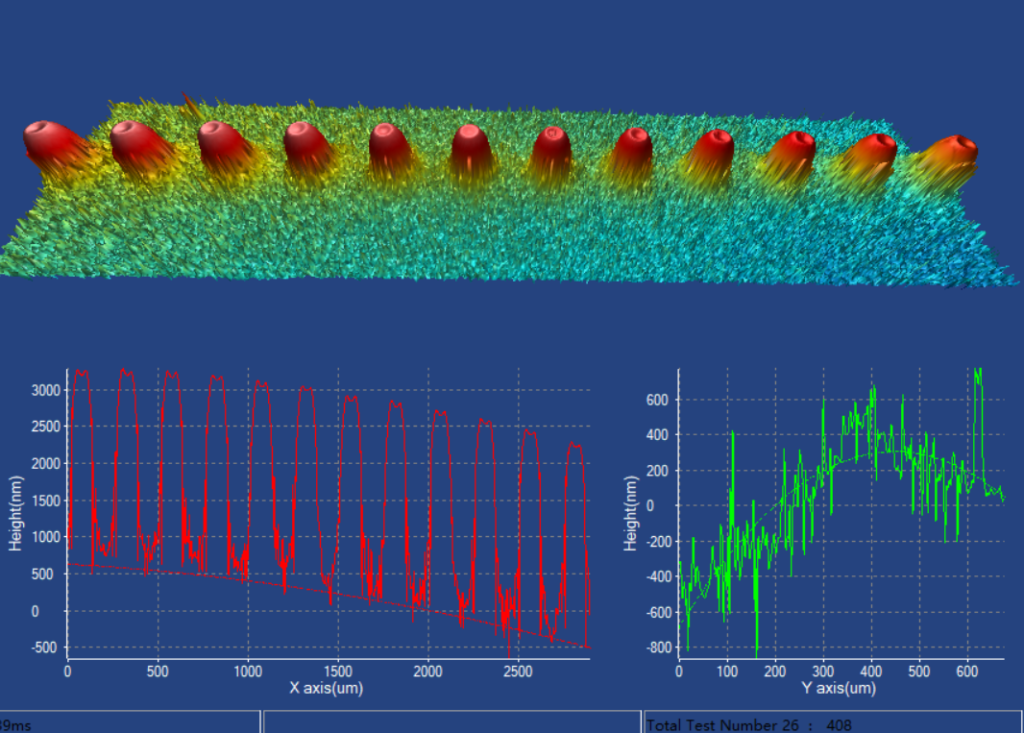

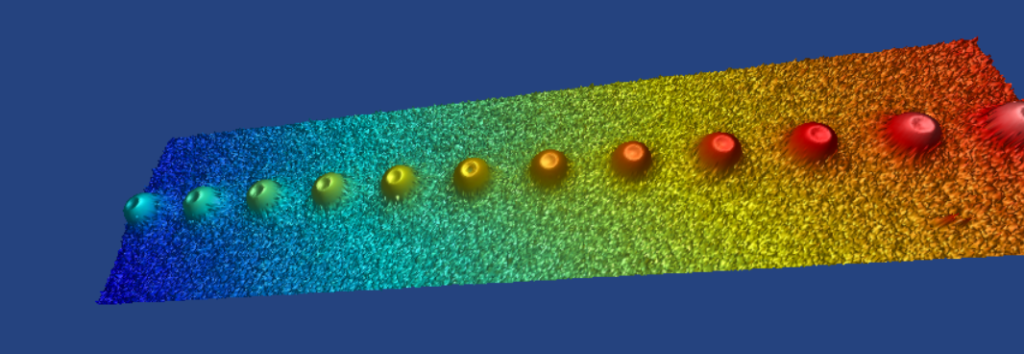

When testing multi-core samples, the device can complete a single measurement in as fast as 3 seconds. For single-core samples, a single measurement can be achieved in as little as 0.3 seconds, making it one of the fastest interferometers on the market. After testing, the device automatically generates high-definition 3D renderings, 2D color maps, and curve fitting graphs, allowing users to intuitively observe the surface morphology of the connectors.

3. Compatibility with Multi-Core and Single-Core Connectors

The device employs a combined white light and red light mode, utilizing a 25?m closed-loop piezoelectric ceramic for precise scanning. Equipped with a high-speed USB 3.0 camera featuring an ultra-large field of view, it is capable of testing all single- and multi-core connectors available on the market. It can test up to 72 cores in a single scan and is compatible with newly introduced MT16 and MT32 connectors, making it suitable for 40G and 100G products. Additionally, it supports single-core connectors such as SC and LC, enabling seamless switching with a single click.

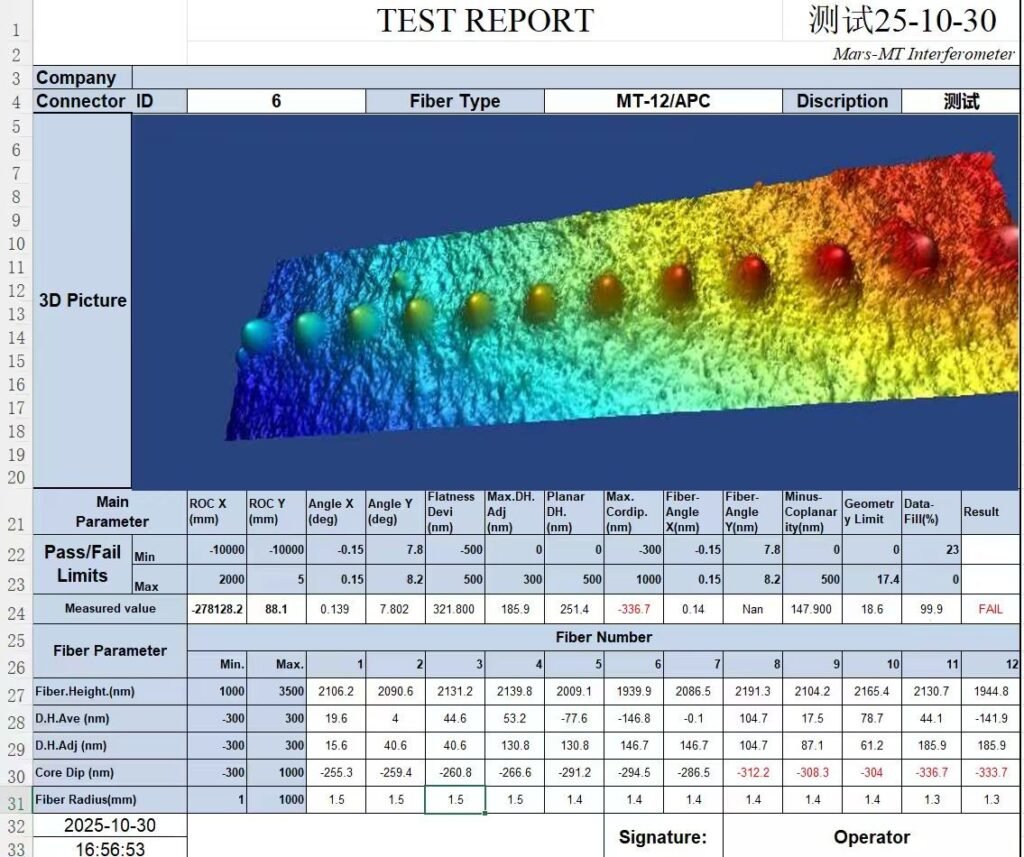

4. High-Definition 3D Reconstruction and Data Fitting

The device incorporates precision optical design and advanced 3D reconstruction algorithms to achieve exceptionally clear imaging results. After each test, it generates ultra-high-resolution 3D color maps, 2D color maps, cross-sectional profiles, and fitting graphs.

5. Comprehensive Fixture Configuration

The device comes equipped with a complete set of interferometer fixtures, primarily including12F/16F interferometer fixtures and multiple adapters such as?MT Ferrule Fixture, MPO Connector Fixture?MMC Connector and MMC Ferrule Fixtures, which can meet the measurement requirements of various single- and multi-core connectors for end users. Additionally, fixtures of various specifications are available as optional accessories or for customization.

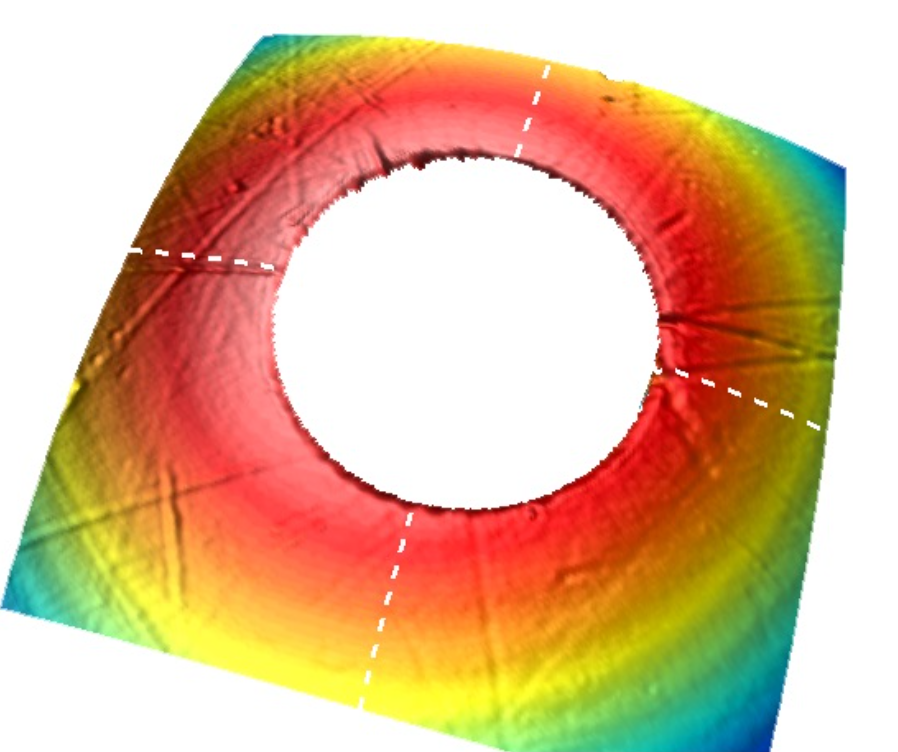

6. Ferrule End-Face Testing

The device can also perform three-dimensional testing of ferrule end faces, measuring parameters such as curvature radius, apex offset, and calculating roughness, scratches, and other features. This function enables ferrule manufacturers to control the end-face polishing quality of their products, thereby enhancing production and processing precision.

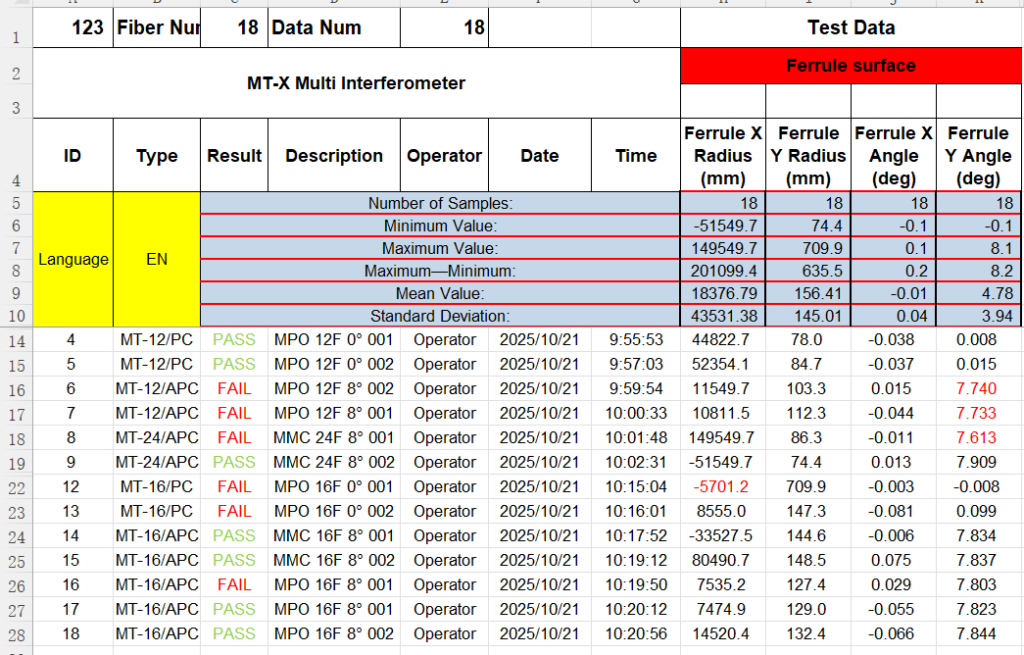

7. Comprehensive Data Report Storage

The device automatically outputs test data and reports during the testing process, facilitating easy archiving and management for users.

Result Format?

Report Format?

To ensure calibration efficiency, we have built four calibration ferrules into the front-mounted tool case. They are ready for immediate use upon opening the lid, enabling quick and effortless calibration.

The front end of the device is equipped with a sponge-padded optical fiber holder, which can securely grip various types of fiber optic connectors. This design effectively prevents fiber displacement during measurement, ensuring the stability and repeatability of test data.

The instrument body is equipped with reinforced mounting feet and threaded holes on both sides. Using the included fixing blocks, the device can be easily and securely anchored to a tabletop to prevent sliding or displacement during operation.